We are one of the leading manufacturing, buying and exporting houses in India. Having recognized the difficulties faced by international importers in perceiving the super-fine quality apparels with the minimum costs, Polestar Garments has begun to help them in offering the apparels with the expected quality and cost range to the international customers.

Manufacturing Services

You design it, we deliver it!

Our team is efficient in providing satisfactory services to our international buyers.

Step 1

Sampling

Step 2

Order Confirmation and BOM

Step 3

The Process of Fabric Making

Yarn

Process

Knitting

Process

Dyeing

Process

Compacting

Process

Fabrics

Washing

Fabrics Relaxation

Fabric Relaxation

The fabrics are relaxed from its roll type tie in the cutting room natural temperature. Relaxation is very important and has to be done before cutting to get fabric’s own shape. The objective of fabric relaxation is to keep fabrics dimensional stability before cutting into garment. Relaxation is necessary for stretch fabrics. Relaxation machines are also used to relax knitted fabrics.

Step 4

Fabric Inspection and Cutting

Step 5

Value Addition (Printing, Embroidery, etc.)

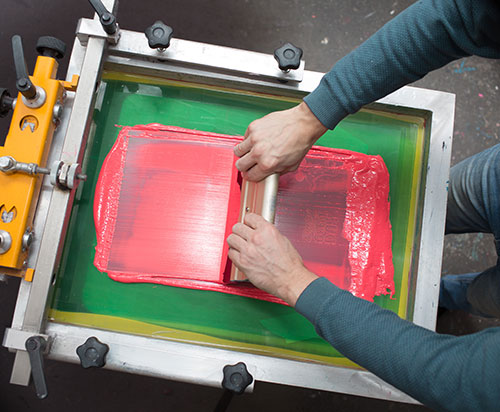

Printing

Process

Embroidery

Process

Applique

Process

Sequins

Process

Heat-transfer

Stickers

Closureand Fasteners

Step 6

Stitching/Sewing

Step 7

Checking, Ironing, Packing

Fabric checking is used to measure the quality level of the incoming fabric.

-

Establishing a standard as a criterion for measuring quality achievement.

-

Production results can be measured and compared to the planned quality standard.

-

Corrective measures to be carried out if there are any deviations in the plans.

Ironing is necessary to smooth away unwanted creases and crush marks.

Packing includes the activities of producing the container for a product and packing.

The strength of our organization rests on the following factors. With these factors we are able to assist our customers with satisfactory services. The factors are:

Step 8

Final Inspection

Once the packaging is completed, there will be a final inspection for the mass production. The packed garments are then inspected for quality assurance of the outgoing finished products. This process is followed for internal quality audit and to ensure that no defective garments are packed into the cartons.

Step 9

Shipping

The strength of our organization rests on the following factors. With these factors we are able to assist our customers with satisfactory services. The factors are:

Quality

The availability of fabric suppliers with super-fine quality.

Partnership

Our partnership with leading manufacturing companies that supply us with defect-free apparels.

Team

Efficient team that clearly understands the requirement of the customers so as to manage the buying and exporting processes to the satisfaction of our customers.

Time

Maintenance of pro-active approach towards the defect identification and taking the corrective measures to ensure timely deliveries.

Price

Flexible and competitively priced.

Network

Chain of networks in ordering, manufacturing, buying and exporting with ease.